Experts in plastic injection moulding

Imagine. Create. Innovate.

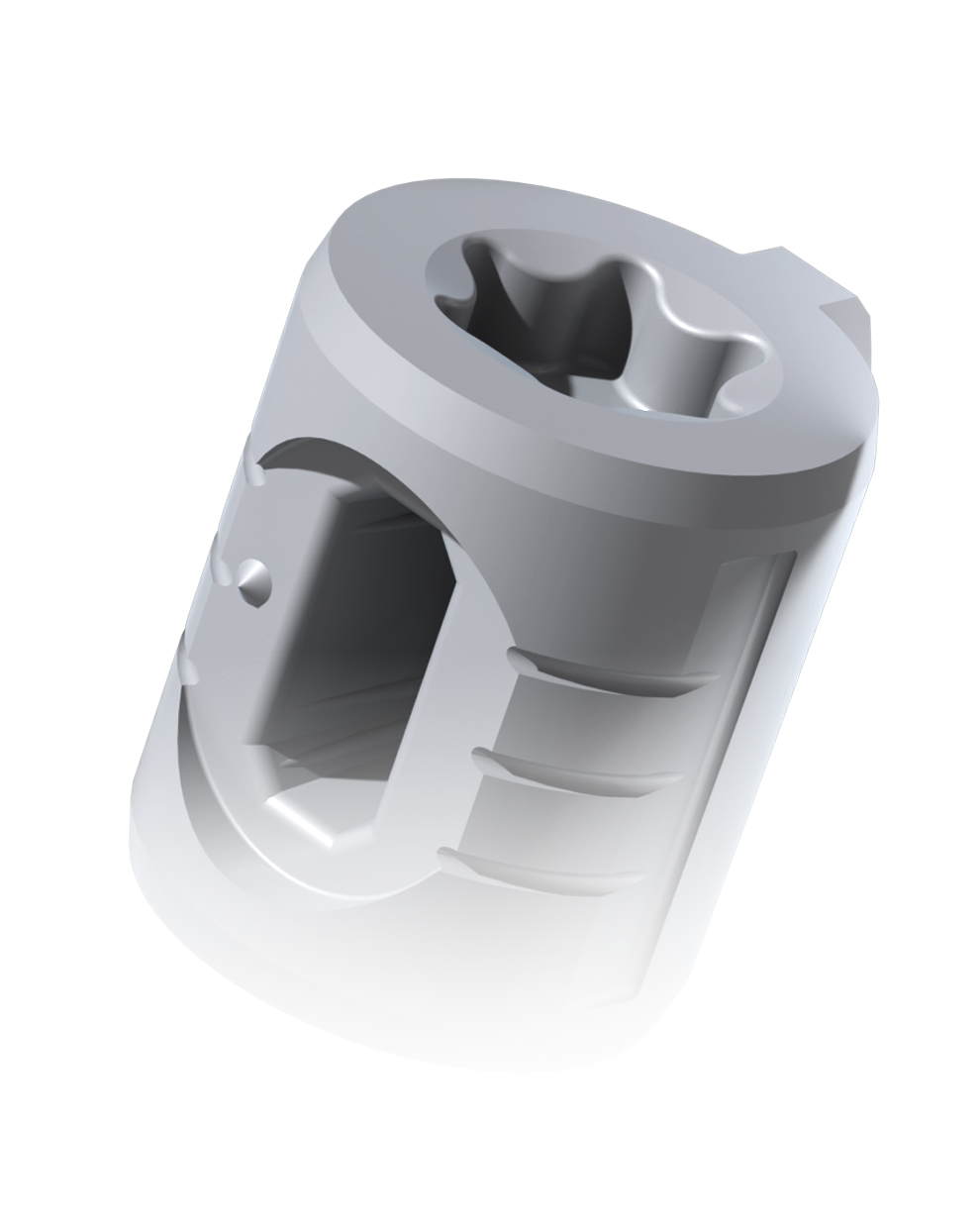

Technique Plastique. Our name says it all. We have the technologies in-house to mould thermoplastics (‘plastics’) into any shape you want. Regardless of the complexity of your end product. No matter what special or extreme properties your semi-finished product needs to possess. We always aim to achieve creative and technical perfection. And conceive, design and mould your product with passion and precision.

Industries.

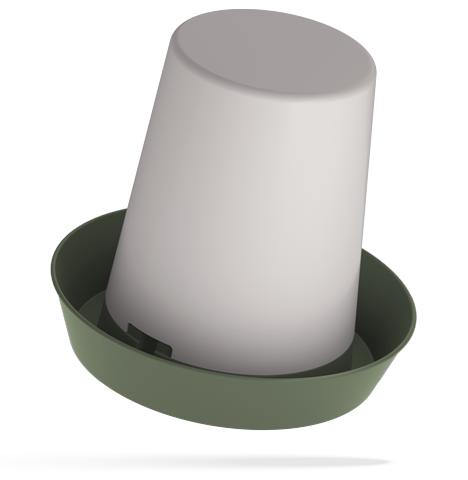

We specialise in plastic injection moulding across a broad spectrum. We produce injection-moulded

products for companies in diverse, often demanding industries.

Inspiring cases.

No matter how novel or outside-the-box your idea may be, we are happy to contribute our expertise and experience from the very beginning. Our designers develop the concepts that make your final plastic product possible. They do so with close attention to both the design and manufacturing feasibility. So engineering is always the 1st step in our total-solution approach.

Our total solution.

Together we go through all the stages, from initial idea development and design of your plastic product to automated production and assembly and the final logistics aspects.

Design

We come up with a creative and manufacturable design in 3D based on your set of requirements.

Mould production

We have the moulds produced, carry out injection trials, and test and validate the product and process.

Injection moulding

After completing validation, we set up the injection moulding process and start production.

We care about our environment

Thought followed by action

Closing the supply chain loop. In other words: collecting, recycling and reusing the plastic products we produce by injection moulding. It is a subject that we consciously consider together with our customers. And actually put into practice.

Our approach includes:

Why choose us?

There are several reasons. We will name a few here:

Range of injection moulding techniques

We are specialists in single shot (1K), two shot (2K), cleanroom and insert & outsert injection moulding, among other techniques.

24/7 automated production

Our production lines are fully automated and run 24 hours a day and 7 days a week to produce your products.

Proven total solution

We carry out and organise the entire process for you. From design and production to assembly and logistics.

Guaranteed quality

We are certified according to ISO 9001 and ISO 134585 (medical devices).

Climate-controlled production environment

We produce your products in a climate-controlled environment with filtered air.

Knowledge of all plastics

We suggest a plastic that has the optimal properties for your product.

Professional team

Our team of experienced experts is always at your disposal to offer you an optimal injection moulding solution.

Research & Development

We develop your product and run simulations in-house.

Focus on sustainability

We actively consider aspects such as the use of biobased plastics and recycling your product.

About Technique Plastique

Our family business was founded in 1995. We specialise in producing plastic products and semi-finished products by injection moulding. From our production facilities in Nederweert, we serve customers all over the world. And we offer customers a total solution: from product design to inventory management.

Questions.

"*" indicates required fields